Timeline Reference: May 1-7, 2025

Sometimes the best sign of progress is when your parts come home looking like they belong in a china cabinet. Part 4 picks up the story the moment the powder coat cured—every bracket queued for quality inspection and inventory packaging.

🎨 Powder-Coat Pick-Up

When I rolled into Company B’s dock I expected the usual cardboard box shuffle. Instead, I found all 18 brackets individually foam-wrapped, stacked on a wooden pallet, and shrink-wrapped tight. The finish? Cardinal wrinkle black—uniform, no rub marks, no “freight rash.”

I’ve worked with three coaters over the years; none of them ever saran-wrapped my gear. Seeing that level of care told me our new fabrication partner and their powder coating partner treat customer parts like their own collection of fine china.

🕵️ Quality-Control Gauntlet

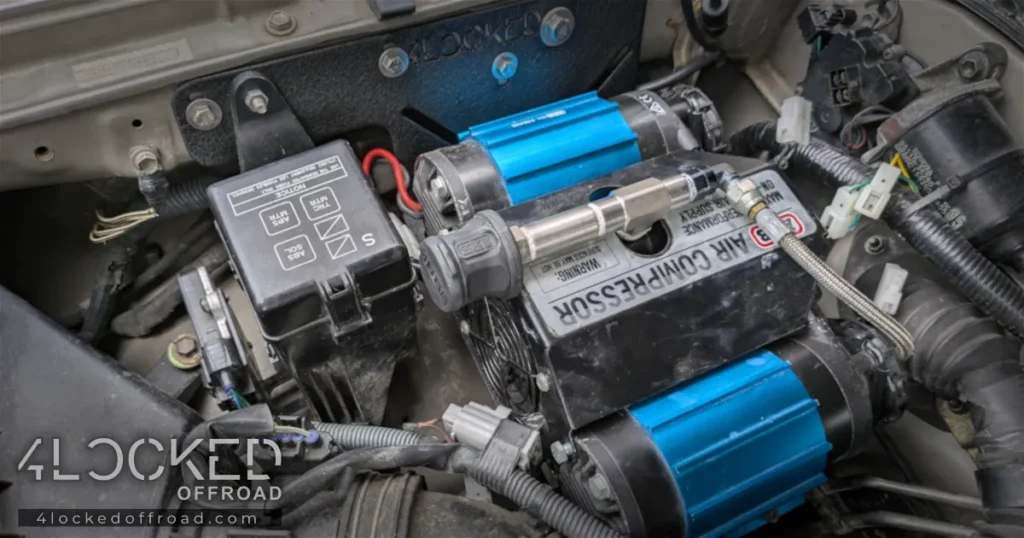

The pallet is still in the back of my 4Runner, wrap intact, while I run each bracket through a four-step QA checklist:

- Visual sweep — hunt for thin spots, gloss variations, or dust inclusions in the wrinkle finish.

- Thread check — run an M6 bolt through every rivet nut and every M6 stud to confirm clean threads.

- Real-world fit test — mount each bracket in my 2002 4Runner’s engine bay to verify hole alignment post-coat.

- Serial-number & sign-off — assign a unique S/N, complete a paper QA sheet, scan it into inventory, and include a hard copy in the box.

📦 Shipping Plan

Once all 18 brackets pass inspection, I’ll finish packaging today and log them in the inventory system. Back-orders should start shipping this Friday, May 9. Watch your inbox for tracking numbers!

📝 Why This Matters

Perfect powder coat is worthless if it shows up scratched. Our manufacturing partners’ pallet job saved rework time, preserved finish integrity, and proved that craftsmanship doesn’t end at the paint booth. That respect for the product matches the respect you have for your rig—and it’s exactly why I switched suppliers.

Thanks for following the journey. Part 5 will dive into final packaging tweaks, the upcoming Light-Duty vs. Heavy-Duty lineup, and how this “one-stop shop” workflow scales for the next run.

Want more updates like this?

Follow along on our social media or check out the Production News archive.