Timeline Reference: May 8-10, 2025

This is the final checkpoint for our April-May bracket batch—the moment every back-order leaves the shop.

🔧 Batch Processing – May 8

With the pallet unwrapped, I ran each bracket through the line:

- Powder-coat scan – flashlight sweep for runs or thin spots.

- Thread test – M6 bolt through every rivet nut and stud.

- Engine-bay fit – quick mount in the ’02 4Runner for final alignment check.

Four brackets picked up a small pin-hole flaw. After the fourth pierce I noticed the parts were slightly offset in the cut file, so I paused the CNC, adjusted the layout, and finished the batch. In the post-cut rush I forgot to weld those punch marks closed. Rather than burn more shop time on re-work, I’m keeping one as a shop display and setting the other three aside for a future clearance sale—or maybe an Instagram giveaway. Stay tuned!

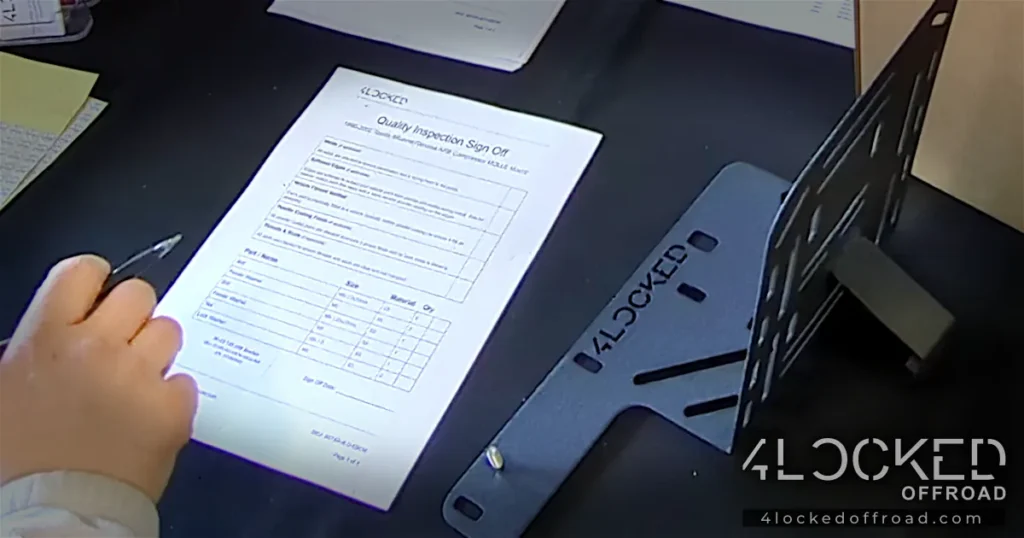

🗂️ Inventory & Serial Numbers – May 9 (AM)

Every cleared bracket received a unique S/N, a signed QA card, and a barcode scan into inventory. Cards are digitized for backup and tucked into each box.

📦 Back-Orders Shipped – May 9 (PM)

Labels printed, tape sealed, pallet rolled onto the truck at 3:45 PM. All back-orders now have tracking numbers in your inbox.

📝 Key Takeaways

- All back-orders are going out with flawless brackets, while four cosmetically defect units are set aside for a future discount or giveaway.

- My four-step QC caught issues early, preventing surprises in your box.

- Shipping goal met: every back-order cleared by Friday, May 9.

Thanks for following the journey—watch our IG stories for a chance to snag a bracket with a tiny cosmetic defect, and stay tuned for the next production run!

Want more updates like this?

Follow along on our social media or check out the Production News archive.